Yellow Orange China 300D/96F Dty Polyester Yarn Eco-friendly Recycle Dty Yarn Fo...

See DetailsDraw texturing is a process used in textile manufacturing to create textured yarns. These yarns have a unique appearance and feel that adds interest and dimension to the finished fabric. In this article, we will explore the draw texturing process and its advantages in creating versatile and innovative textiles.

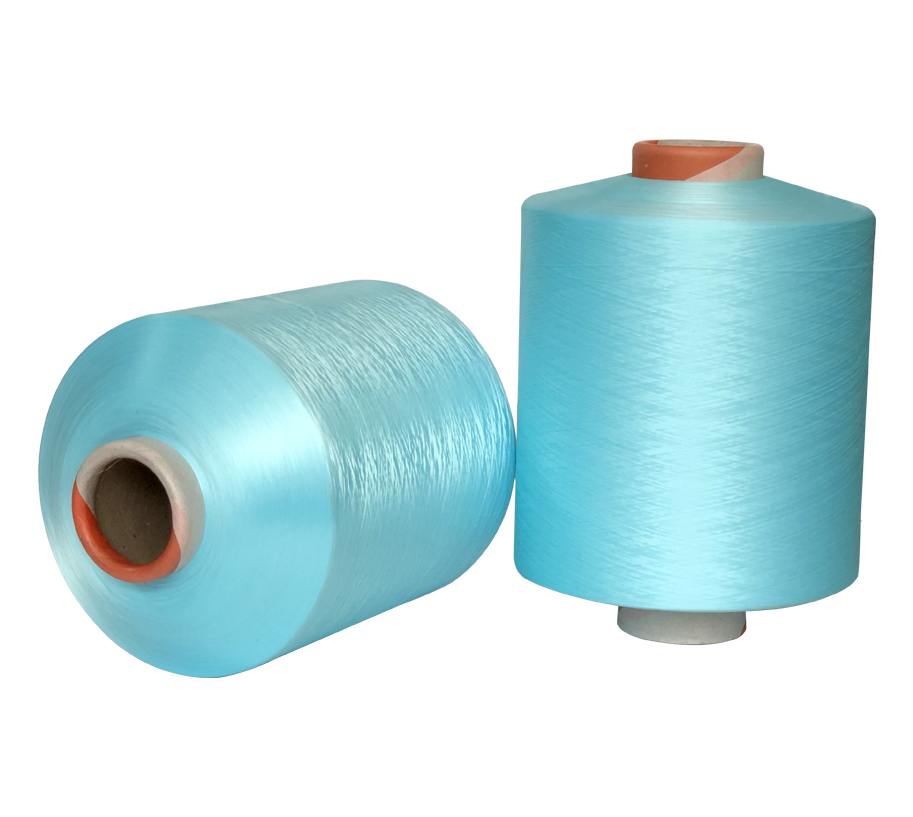

Draw texturing involves the transformation of continuous filament yarns into textured yarns. It is achieved through the controlled application of heat and tension. During the process, the filaments are heated and then rapidly cooled, which causes them to crimp and curl. This crimping and curling create a textured effect in the yarn, resulting in a visually appealing and interesting fabric.

One of the main benefits of draw texturing is the ability to create a wide range of yarn textures. By adjusting various parameters such as the heating temperature and cooling rate, manufacturers can create different levels of texture and curl in the yarn. This versatility allows for the production of yarns with varying degrees of softness and surface aesthetics.

Another advantage of draw texturing yarn is its stretchability. The crimped structure of the yarn allows it to expand and contract, giving the fabric made from it stretch and recovery properties. This makes it an ideal choice for applications where stretch and elasticity are desired, such as sportswear, activewear, and lingerie.

Furthermore, draw texturing can be used to create yarns with different thicknesses and densities. By adjusting the tension and speed during the process, manufacturers can produce yarns with varying thicknesses, which can then be used to create fabrics with different levels of opacity and transparency. This versatility opens up a world of possibilities for designers, allowing them to experiment with a wide range of fabric weights and textures.

Draw texturing yarns are also highly compatible with dyeing and printing processes. The crimp and curl in the yarn's structure allow for better dye penetration, resulting in vibrant and uniform coloration throughout the fabric. Additionally, the texture created during draw texturing can enhance the visual effects of prints, creating unique and eye-catching designs.