White/Brown/Green 150D/48F DTY Yarn 99.99% Polyester AA Grade Eco-friendly Yarn ...

See DetailsThe following measures are mainly taken to improve the doffing retention rate:

Choose a suitable traveler and adjust the distance of the traveler cleaner to prevent or reduce the traveler hanging flowers. Adjust the number of loops of the waste wire reel to prevent the normal movement of the traveler due to excessive wire return, and prevent the deterioration of the "little braid" and cause breakage. The number of turns of the waste spool can be adjusted by the following parameters: spindle off-spindle braking time (3 seconds); ring plate down-spindle off time (0 ~ 0.5 seconds); doffing spindle speed (5500 ~ 6500 rpm) ); the falling speed of the doffing ring plate; when the combination of the above four adjustments can not reach the ideal number of loops, check whether the electromagnetic brake system is in good condition. The waste silk reel should be cleaned up once a week, and the number of cleanings can be increased according to the situation of the waste silk when spinning thicker yarns.

Set the appropriate middle yarn position and start-up spindle speed to ensure that the balloon does not touch the end of the spinning tube or the spacer plate, and the distance between the fender and the spinning tube must be kept appropriate. The doffing time of the automatic doffing system is about 260 seconds, and the end retention rate is higher than that of manual or manual and then automatic end retention. Therefore, the automatic doffing system should be used instead of manual. The doffing worker should check the rewinding of the spindle during doffing. If it is found that there is rewinding of the spindle, it must be cleaned in time to prevent the rewinding of the spindle from obstructing the movement of the traveler, resulting in "small braids" and breaking ends.

Check every day whether the blower and suction fan work well. Prevent the accumulation of flowers due to the poor function of the blower and suction fan, resulting in yarn defects and embossing of the convex disc, causing the convex disc to be immovable or misaligned, affecting the grabbing and normal doffing. The belly of the spinning car is cleaned by a dedicated person, once per shift, to prevent the spinning belly from floating and causing the spinning to break. The pipe grabber, bobbin and Machine parts should be picked up in time to prevent the air frame from being dislocated after the air frame rocker arm is topped and affecting the doffing. The convex disk track is cleaned once every 15 days with the wiper to prevent the convex disk track from accumulating, causing the convex disk to be misaligned and affecting the doffing. The doffing air frame shall be checked and leveled once after 15 days with the car to prevent the air frame from being incorrectly positioned and affecting the normal doffing. All parts are checked and cleaned by photoelectric in time to prevent photoelectric failure from affecting normal doffing. Spinning bobbins should be picked regularly to remove unqualified bobbins.

When using a long cart for the time, for safety reasons, the equipment manufacturer will recommend the manual and then automatic method, that is, the doffing knob is set to the manual position during normal production, and after the doffing warning light flashes, the doffer will check the cart. Check if there is any abnormality, then turn the doffing knob to the automatic position and start the automatic operation procedure. The advantage of this is to prevent accidents caused by negligence of equipment and personnel. The disadvantage is that the doffing knob is turned on manually and the servo motor is always energized, which will seriously shorten the service life of the servo motor.

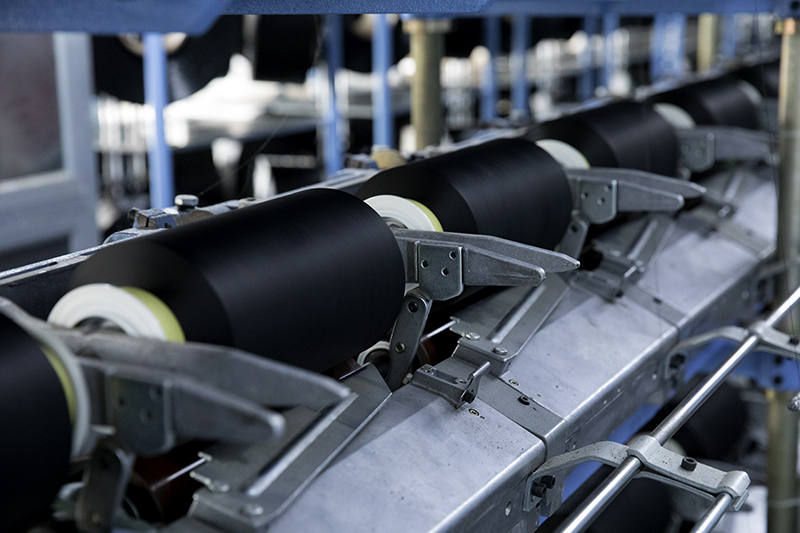

Long cars use aluminum casing spindles, and they are equipped with spindle brakes. The aluminum sleeve spindle is equipped with a thin-arm spinning tube, and the tight fit between the spinning tube and the spindle is mainly realized by three elastic shells on the upper part of the spindle. When the spindle is running, the centrifugal force will cause the "cat's eye" to withstand the inner wall of the spinning tube to achieve a tight fit between the tube and the spindle. Some spinning gear workers are not accustomed to using brakes, and some workers suspect that the speed of jointing using the brakes is slow, and there will be a phenomenon of pulling the yarn directly without the brakes. This will cause the cat's eye of the spindle to fall off and damage the inner arm of the bobbin, which will damage the bobbin and affect the yarn quality, which is very harmful. So we must prevent this from happening. In addition, if the spindle brake is braked on the spindle for a long time, it will cause the spindle to become hot, the brake spindle will burn out, the spindle belt will burn out, and even the spindle will be burned out. Therefore, we must prevent this kind of bad operation. It is also necessary to avoid doffing of adjacent Machines at the same time to ensure safety.

When changing the variety, both the front and rear of the car need to modify the draft gear, which must be checked carefully, otherwise it will cause misalignment. When sampling the spinning head yarn, both the front and rear of the car must be taken to prevent errors. It is necessary to prevent the wiper from being left on the fender when the fender is turned up, causing damage to the Machine parts. The power distribution system must have a harmonic processing device when the equipment is installed to prevent harmonic interference from causing unstable equipment operation and poor cop forming. When wiring the spinning car, the power line and the data signal line are required to be separated, which can prevent the data signal line from being interfered with and causing the equipment to malfunction.