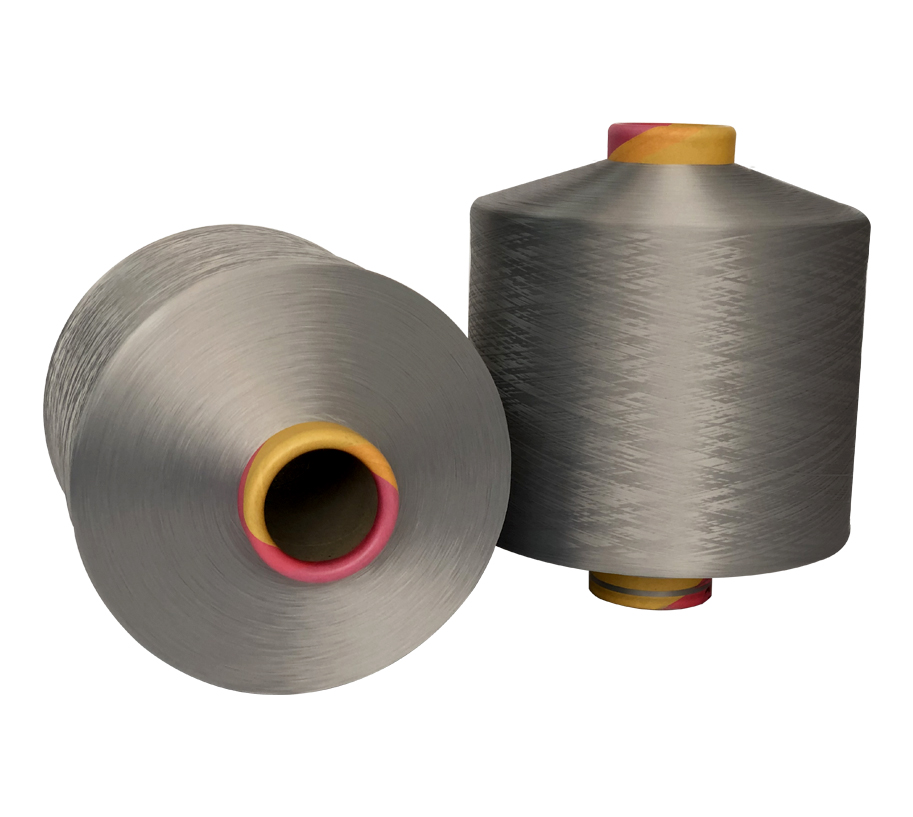

White/Brown/Green 150D/48F DTY Yarn 99.99% Polyester AA Grade Eco-friendly Yarn ...

See DetailsIn the textile industry, the demand for high-quality fabrics has been on the rise. Manufacturers are constantly exploring innovative techniques to produce materials that are durable, lightweight, and visually appealing. One such advancement in yarn production is the development of high intermingle yarn. This revolutionary process has significantly improved the quality and performance of fabrics, propelling the textile industry to greater heights.

High intermingle yarn refers to yarn that has undergone a specific treatment to enhance its interlocking capability. Traditionally, yarns were created by twisting fibers together, resulting in a relatively weak and easily unraveled structure. However, high intermingle yarn incorporates an additional step in the production process where the twist is mechanically intermingled, ensuring a more secure and compact structure.

The intermingling process significantly enhances the integrity of the yarn, offering numerous benefits to fabric manufacturers and end-users. Firstly, high intermingle yarn provides strength and durability. The interlocking mechanism prevents the yarn from easily unraveling, even under high tension or repeated stress. This makes fabrics made from high intermingle yarn more resistant to tearing, thereby resulting in longer-lasting products.

Moreover, high intermingle yarn contributes to improved fabric performance. Fabrics made from this yarn exhibit elasticity, allowing them to stretch and recover without losing their shape. This is particularly advantageous for sportswear and activewear, where flexibility and freedom of movement are essential. Additionally, the interlocked structure of the yarn creates a more uniform fabric surface, reducing the occurrence of snags or pilling.

Furthermore, high intermingle yarn enhances the visual appeal of fabrics. The interlocking mechanism creates a three-dimensional effect, adding depth and texture to the material. This unique feature allows designers to create visually striking patterns and designs that cannot be achieved with conventional yarn. Fabrics made from high intermingle yarn often have a luxurious appearance, making them highly sought after in the fashion industry.

In terms of production efficiency, high intermingle yarn also offers advantages. The intermingling process can be easily incorporated into existing spinning and twisting Machines, minimizing the need for additional equipment or specialized setups. This means that manufacturers can swiftly adopt this new process without significant disruptions to their production lines.

The adoption of high intermingle yarn has revolutionized the textile industry, offering a multitude of benefits to manufacturers and consumers alike. From enhanced strength and durability to improved fabric performance and visual appeal, this innovative yarn has elevated the quality of fabrics produced today. Additionally, the process of intermingling does not require extensive modifications to existing Machinery, making it a feasible and cost-effective solution for textile manufacturers looking to enhance their product offerings.