Navy/Grey 150D/36F DTY Yarn 99.99% Polyester Anti-pilling Yarn for Sewing Materi...

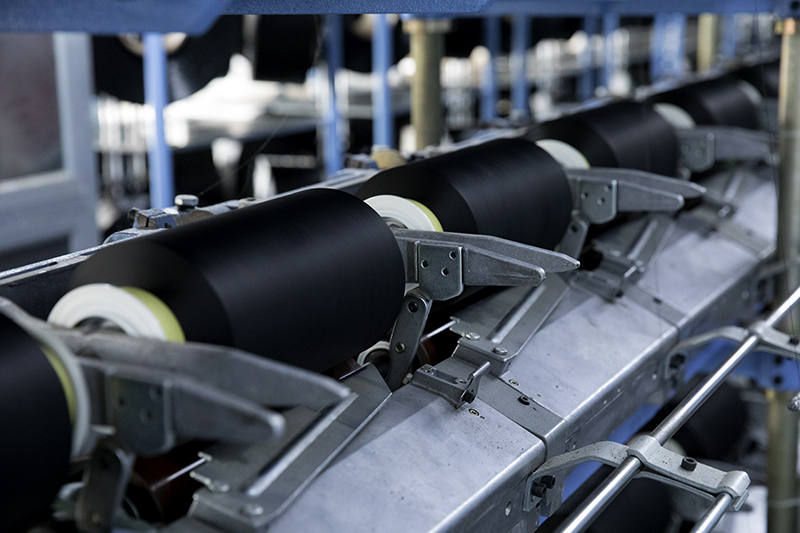

See DetailsWhether the apron can run synchronously with the middle and bottom rollers, strictly speaking, there are factors of the apron itself, spinning equipment and process environment, and whether the apron can synchronously transport the fiber to the front rubber roller for pulling under the elastic grip. Stretching into yarn makes the fiber shift point move forward steadily, which puts high demands on aprons.

1. Appearance requirements

"Light, slippery, dry, cool" has been used for a long time. Many people think that the smoother the better, but this is not the case. Excessive "slip" will result in a decrease in the holding power of the aprons to the yarn. The holding power of the upper and lower aprons on the fiber is composed of several factors, one is the dynamic friction coefficient of the upper and lower aprons; the other is the contact geometry of the upper and lower aprons; The third is the spring pressure and the size of the spacer block; the fourth is the contact area between the apron and the yarn, temperature and humidity, etc., if only the influence of the dynamic friction coefficient of the apron on the fiber holding force is analyzed, the rubber The ring not only has a considerable dynamic friction coefficient, but also the static friction coefficient is higher than the front rubber roller, and the friction coefficient of the upper ring should be greater than that of the lower ring.

2. Internal surface requirements

Because the surface after acid treatment is wetter and the rotation resistance increases, the apron line speed and the roller line speed are quite different, especially the winding speed is slower, which has a serious impact on the yarn evenness. In recent years, the application of internal pattern aprons has helped solve this problem, and the evenness level has been significantly improved, generally within 0.5%. It also proves that the inner surface of the apron must have smoothness and roughness in order to speed up the rotation speed of the apron. Synchronization with the line speed of the middle roller is the basic standard for the inner and outer surfaces of the apron.

3. Requirements for upper and lower rubber rings

According to the requirements of traditional habits, some performance combinations of the upper and lower aprons of the spun yarn are usually thin at the top and thick at the bottom, and soft at the top and hard at the bottom. The so-called upper and lower thickness mainly refers to the choice and arrangement of the upper and lower aprons specifications and thickness; the upper soft and the lower hard, mainly refers to the choice and arrangement of the inner layer strength of the lower aprons due to their different functions, and the main function is to require glue During the operation of the circle, it sticks and is soft and passive. In addition, when rotating, the friction factor and the friction contact surface are much lower than the aprons, so the difference in linear speed of the aprons is generally small.

4. The spinning performance of aprons

A good spinning apron must have certain spinnability in the long-term production process. The smoothness and dryness of the outer layer of the aprons not only ensure that the upper and lower aprons have no stickiness during the process of holding and conveying the drafting yarn, but also the inner and outer surfaces of the upper and lower aprons must have a relatively stable friction coefficient. During operation, the slip rate between the three pairs of friction bodies of the lower apron and the bottom roller, the upper and lower aprons, and the upper apron and the upper roller should be reduced to a , and the resistance between the upper and lower aprons and the upper and lower jaw jaws should be as small as possible , So as to ensure the stable delivery of the drafted yarn and stabilize the normal operation of the process. Not only can spin high and low counts, but also adapt to non-cotton products.

5. The service life of the rubber ring

The service life of the apron is also an important indicator to measure the pros and cons of the apron. It is not only related to the good quality of the yarn produced by the enterprise, but also affects the cost of the enterprise. Therefore, the apron must have small surface wear and small elastic variation, etc., in a certain time period Meet the yarn quality requirements.