Navy/Grey 150D/36F DTY Yarn 99.99% Polyester Anti-pilling Yarn for Sewing Material: 99.99% polyester...

See Details300D/96F RW NIM Polyester Yarn

-- Steady & Reliable Manufacturer --

Introduction

Hangzhou Dingkai Chemical Fibre Co., Ltd. (DK) is a leading factory for 300D/96F RW NIM polyester yarns. Within our 15,000 sqm Hangzhou facility, we utilize 30 advanced DTY machines to produce Grade AA yarns that satisfy international quality benchmarks. Since 2007, our NIM series has been a critical component for B2B exporters and textile mills in South Korea, Southeast Asia, and Russia who require smooth, high-quality polyester raw materials for precision manufacturing.

Detailed Professional Description

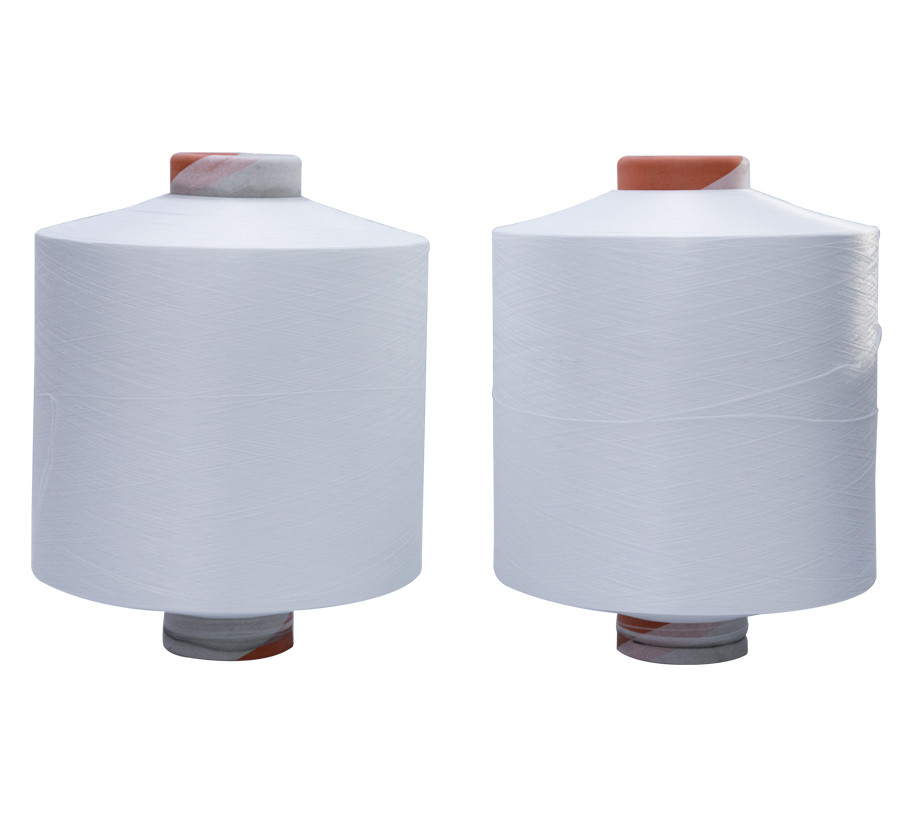

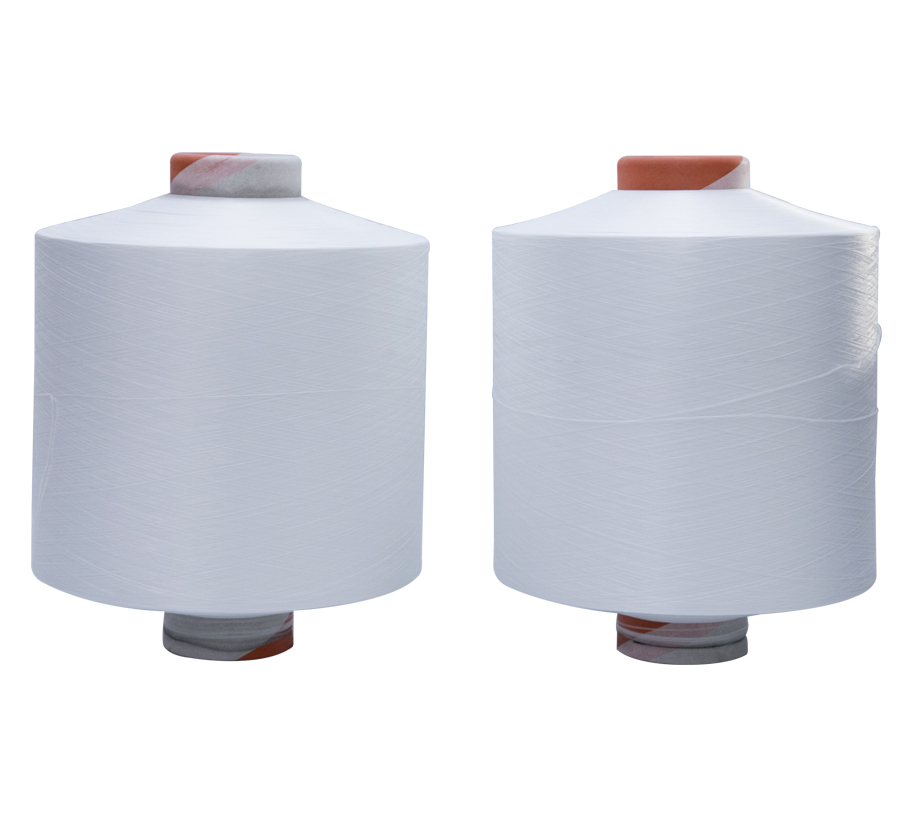

The 300D/96F Raw White (RW) NIM (Non-Intermingled) polyester yarn is a smooth-profile DTY filament designed for processes requiring zero filament entanglement. Featuring 96 individual filaments, this yarn provides a soft, voluminous feel with excellent fabric coverage. The NIM configuration ensures a completely smooth surface, making it ideal for high-end circular knitting or applications where the yarn will undergo secondary processing like sizing or high-twisting. In its Raw White state, it offers a high degree of dye affinity for versatile finishing.

Application Fields

Circular Knitting: Applied in jersey and interlock fabrics where a perfectly smooth surface is required.

Twisting Base: Used as the primary yarn for the production of plied or high-twist industrial yarns.

Home Textiles: Applied in premium bedsheets and pillowcases requiring a node-free, soft texture.

Sizing Warp: Used as a warp yarn in weaving after a sizing process for filament protection.

Specification Overview

| Denier/Filament | 300D/96F |

| Intermingle Type | NIM (Non-Intermingle) |

| Color/Luster | Raw White (RW) / Semi-Dull (SD) |

| Tenacity | ≥ 3.2 cN/dtex |

| Elongation | 24.0% ± 3.0% |

| Grade | Grade AA |

Production Process & Customization Service

Production involves draw-texturing with the air-jet intermingling unit disabled. Customization includes:

Filament Adjustment: Can be customized to 72F or 144F to modify the fabric's body and softness.

BWS Control: Boiling Water Shrinkage can be tailored for specific fabric stability requirements.

Luster Options: Available in Semi-Dull, Bright, or Full Dull variants.

Frequently Asked Questions (FAQ)

Q: Why choose 300D/96F NIM over HIM?

A: NIM is preferred when the final product requires a very smooth look without the visual texture of intermingle nodes, or when the yarn will be sized before weaving.

Q: Does 300D/96F NIM require special handling?

A: Because there are no intermingle nodes, the filaments are loose. Proper tension control during unwinding is essential to prevent filament snagging.

Based on the continuing flourish of business, the company was committed to our own brand and insists on good quality of DTY yarn. We are China 300D/96F RW NIM Polyester Yarn Manufacturers and Wholesale 300D/96F RW NIM Polyester Yarn OEM/ODM Suppliers. Covering an area of 15,000 square meters, the company has 30 DTY machines.

Mainly exported to over 30 countries such as Vietnam, Cambodia, Myanmar, South Korea, Ukraine, Russia, Morocco, the Philippines, Mexico and etc.Our main yarn products include polyester DTY yarn, polyester Sd yarn, high intermingled yarn, polyester raw material. They all meet the Grade A and Grade AA .

Color & Dyeing Methods

Our 300D/96F RW NIM is designed for high-quality piece dyeing. The absence of intermingle knots prevents the occurrence of "dye spots" or uneven color take-up. The Raw White base is strictly monitored to ensure it is free from spinning oils or contaminants, allowing for vibrant and deep color development in all shades.