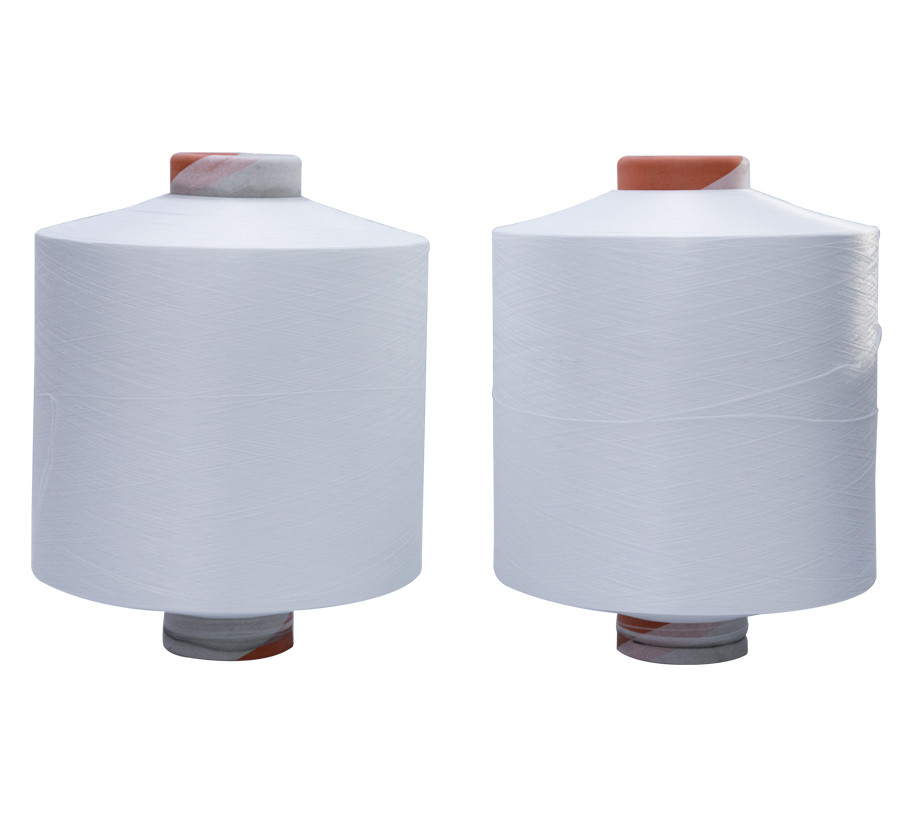

Navy/Grey 150D/36F DTY Yarn 99.99% Polyester Anti-pilling Yarn for Sewing Material: 99.99% polyester...

See Details150D/48F RW HIM

-- Steady & Reliable Manufacturer --

Introduction

Hangzhou Dingkai Chemical Fibre Co., Ltd. (DK) specializes in High Intermingled (HIM) technology, producing 150D/48F RW HIM yarns that meet the highest industrial standards. From our 15,000 sqm facility in Hangzhou, we utilize advanced air-jet units on our 30 DTY machines to ensure consistent node strength and frequency. Our HIM products are exported globally to manufacturers in Russia, Ukraine, and Mexico, providing a robust solution for weaving mills that require sizing-free warp yarns.

Detailed Professional Description

The 150D/48F Raw White (RW) High Intermingled (HIM) yarn is a polyester DTY specification engineered with strong mechanical nodes. These nodes, created by high-pressure air jets, ensure that the 48 filaments remain tightly cohesive throughout the textile production process. HIM yarn is specifically designed for high-speed weaving and knitting where filament separation would cause machine downtime or fabric defects. The yarn maintains a balance of bulkiness (from texturing) and structural integrity (from intermingling).

Application Fields

Warp Weaving: Suitable for use as warp yarn without the need for sizing, reducing production costs.

High-Speed Knitting: Prevents filament breakage and "snowing" on high-speed circular knitting machines.

Technical Textiles: Used in industrial fabrics where yarn cohesion is critical under mechanical tension.

Upholstery: Applied in durable home textiles that undergo heavy finishing processes.

Specification Overview

| Denier/Filament | 150D/48F |

| Intermingle Type | HIM (High Intermingle) |

| Node Count | 80 - 120 knots/meter |

| Color/Luster | Raw White (RW) / Semi-Dull (SD) |

| Tenacity | ≥ 3.3 cN/dtex |

| Grade | Grade AA / Grade A |

Production Process & Customization Service

HIM yarn is produced by passing the textured filament through high-pressure air nozzles. Customization includes:

Node Strength: Adjusting air pressure to create "hard" nodes for weaving or "soft" nodes for specific knitting needs.

Twist Combination: We can combine HIM with S or Z twists for torque-balanced applications.

Tailored Denier: Adjusting the total denier to meet specific fabric weight requirements (e.g., 145D or 155D).

Frequently Asked Questions (FAQ)

Q: What is the typical node frequency for DK’s HIM yarn?

A: Our 150D/48F HIM usually features 80 to 120 nodes per meter, but this can be adjusted based on the specific requirements of your weaving or knitting equipment.

Q: Does HIM affect the hand feel of the final fabric?

A: HIM yarn results in a slightly firmer texture compared to NIM. However, after the dyeing and finishing process, the nodes soften significantly, providing a standard DTY hand feel.

Based on the continuing flourish of business, the company was committed to our own brand and insists on good quality of DTY yarn. We are China 150D/48F RW HIM Manufacturers and Wholesale 150D/48F RW HIM OEM/ODM Suppliers. Covering an area of 15,000 square meters, the company has 30 DTY machines.

Mainly exported to over 30 countries such as Vietnam, Cambodia, Myanmar, South Korea, Ukraine, Russia, Morocco, the Philippines, Mexico and etc.Our main yarn products include polyester DTY yarn, polyester Sd yarn, high intermingled yarn, polyester raw material. They all meet the Grade A and Grade AA .

Color & Dyeing Methods

Our 150D/48F RW HIM is optimized for high-pressure piece dyeing. The intermingle nodes are mechanically stable enough to withstand the turbulence of dyeing machines without opening. The Raw White base ensures excellent color reproduction for light, medium, and dark shades across various fabric types.