Navy/Grey 150D/36F DTY Yarn 99.99% Polyester Anti-pilling Yarn for Sewing Material: 99.99% polyester...

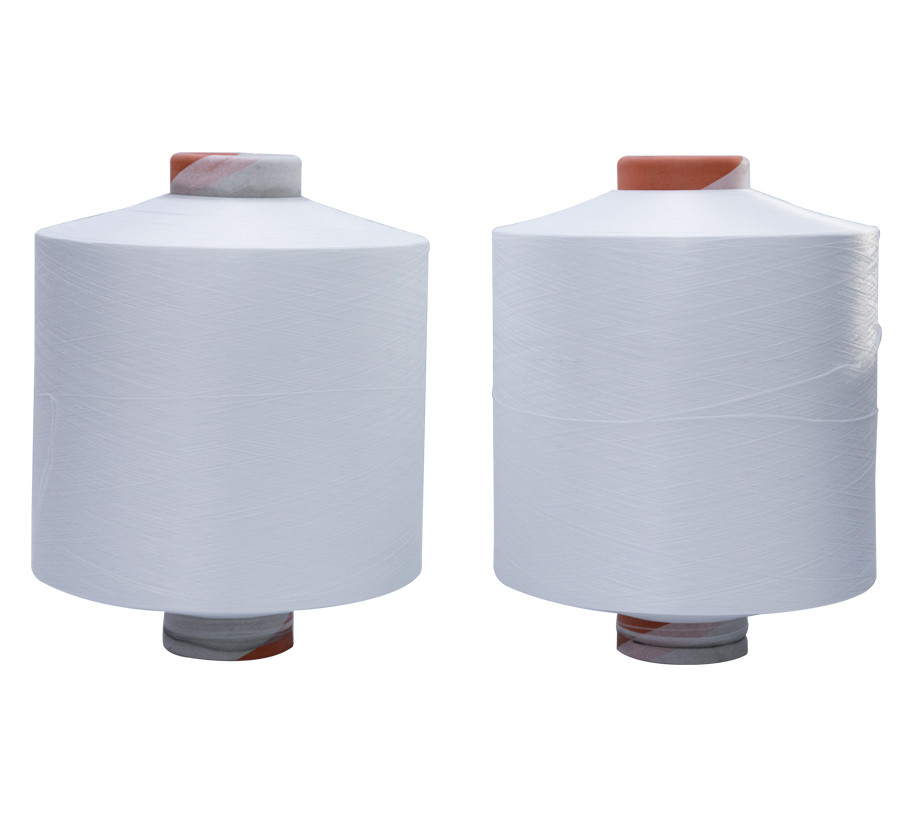

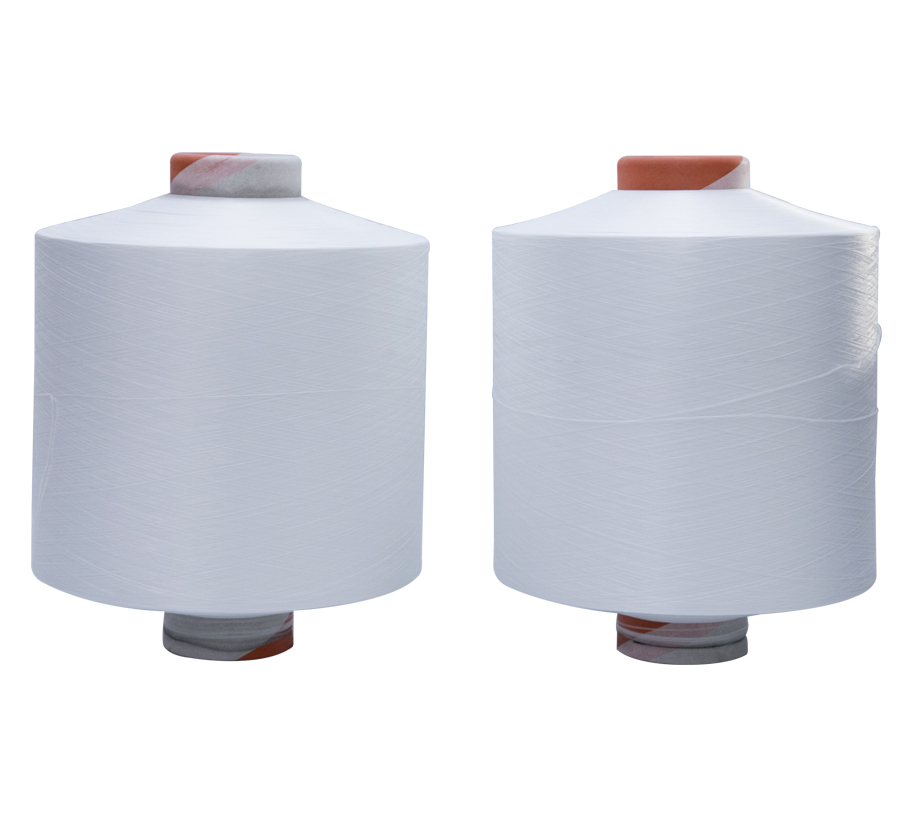

See Details150D/48F RW NIM

-- Steady & Reliable Manufacturer --

Introduction

As a leading China polyester yarns manufacturer, Hangzhou Dingkai Chemical Fibre Co., Ltd. produces 150D/48F RW NIM yarn for high-precision knitting and weaving. Operating out of a 15,000 sqm factory with 30 DTY machines, we ensure that our NIM series is free from mechanical knots, meeting Grade AA standards. Our 150D/48F NIM is a core export product, reaching textile mills in Cambodia, Myanmar, and South Korea that demand smooth, high-quality polyester raw materials.

Detailed Professional Description

The 150D/48F Raw White (RW) Non-Intermingled (NIM) yarn is a smooth polyester filament designed for processes where zero inter-filament entanglement is required. Unlike intermingled yarns, NIM variants provide a completely smooth profile, allowing for a flatter fabric appearance and specific textures in circular knitting. The 48-filament count ensures a soft dtex per filament, providing a balance between yarn strength and flexibility. This specification is manufactured under tight temperature controls to ensure consistent boiling water shrinkage (BWS) and dye affinity.

Application Fields

Circular Knitting: Applied in jersey fabrics where a smooth, node-free surface is required.

Sizing Weaving: Used as warp yarn after a sizing process to provide protection during weaving.

Twisting Base: Serves as the primary yarn for further plying or high-twist yarn production.

Hosiery: Used in parts of socks and tights where intermingle nodes might cause skin irritation or visual defects.

Specification Overview

| Denier/Filament | 150D/48F |

| Intermingle Type | NIM (Non-Intermingle) |

| Color/Luster | Raw White (RW) / Semi-Dull (SD) |

| Tenacity | ≥ 3.2 cN/dtex |

| Elongation | 22.0% ± 3.0% |

| Grade | Grade AA |

Production Process & Customization Service

The NIM variant is produced by bypassing the air-jet intermingling unit during texturing. Customization includes:

BWS Adjustment: Boiling Water Shrinkage can be tailored to match specific fabric finishing requirements.

Oil Content: OPU can be adjusted (e.g., 2% to 5%) to provide the necessary lubrication for different knitting speeds.

Luster: Bright or Full Dull versions of 150D/48F NIM can be manufactured upon request.

Frequently Asked Questions (FAQ)

Q: Why choose NIM over HIM for 150D/48F?

A: NIM is preferred when the final fabric requires a very smooth look or when the yarn will undergo a secondary process like sizing or high-twisting. HIM is better for direct weaving without sizing.

Q: Is there a risk of filament separation in NIM yarn?

A: Since NIM has no nodes, the filaments are loose. This requires careful handling during unwinding and is usually processed with appropriate tension or sizing.

Based on the continuing flourish of business, the company was committed to our own brand and insists on good quality of DTY yarn. We are China 150D/48F RW NIM Manufacturers and Wholesale 150D/48F RW NIM OEM/ODM Suppliers. Covering an area of 15,000 square meters, the company has 30 DTY machines.

Mainly exported to over 30 countries such as Vietnam, Cambodia, Myanmar, South Korea, Ukraine, Russia, Morocco, the Philippines, Mexico and etc.Our main yarn products include polyester DTY yarn, polyester Sd yarn, high intermingled yarn, polyester raw material. They all meet the Grade A and Grade AA .

Color & Dyeing Methods

Our 150D/48F RW NIM is designed for piece dyeing in a wide range of shades. The Raw White finish is highly absorbent to disperse dyes. Because it is NIM, it ensures that the dye liquor can flow through the filament bundle evenly, preventing uneven coloration in dense fabric structures.