Navy/Grey 150D/36F DTY Yarn 99.99% Polyester Anti-pilling Yarn for Sewing Material: 99.99% polyester...

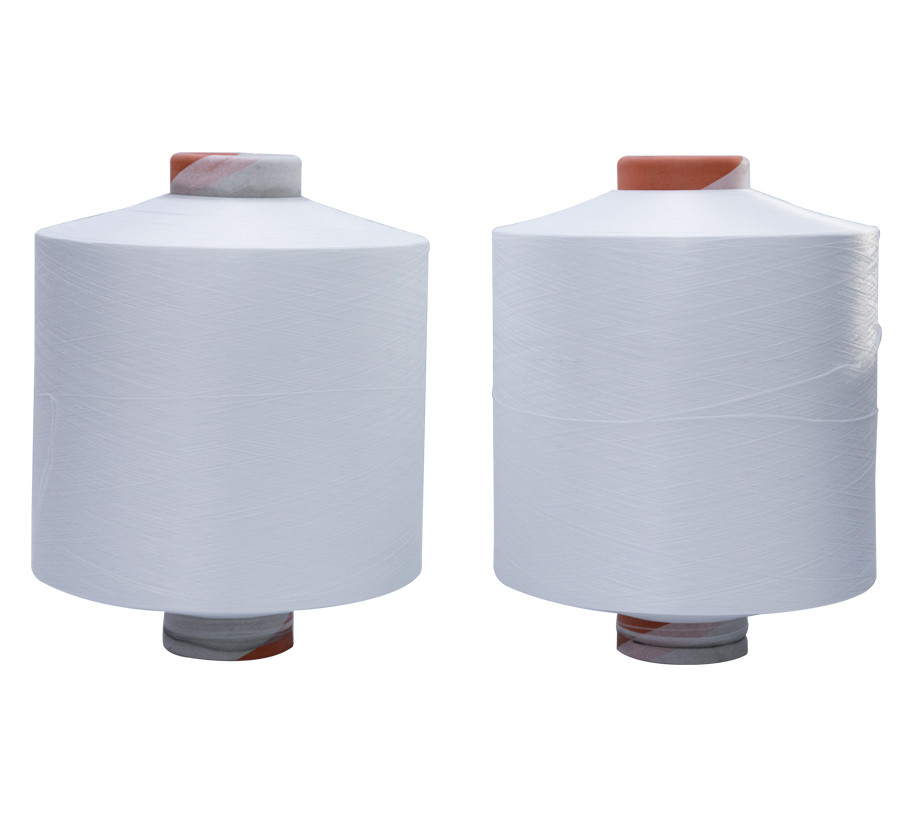

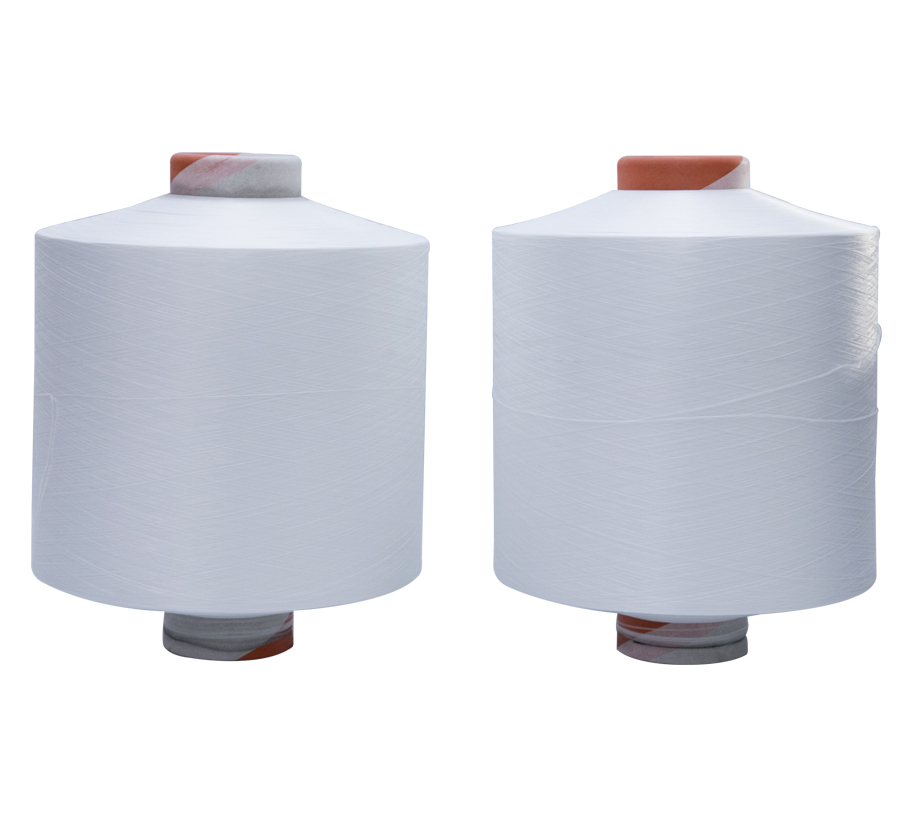

See Details75D/72F RW SIM Polyester Yarn

-- Steady & Reliable Manufacturer --

Introduction

Hangzhou Dingkai Chemical Fibre Co., Ltd. (DK) is a specialist in micro-filament DTY, producing Grade AA 75D/72F RW SIM yarns at our 15,000 sqm Hangzhou facility. Since 2007, we have utilized 30 advanced DTY machines with precision air-jet units to ensure consistent node frequency. We export this high-performance specification to over 30 countries, supporting B2B clients in the luxury apparel and technical textile sectors who demand the softness of micro-fibers with industrial-grade efficiency.

Detailed Professional Description

The 75D/72F Raw White (RW) SIM (Slightly Intermingled) polyester yarn represents the pinnacle of micro-filament engineering combined with process stability. With 72 filaments in a 75 denier bundle, it features a dpf (denier per filament) of approximately 1.04. The SIM configuration introduces subtle mechanical nodes that provide essential filament cohesion for high-speed textile machinery without compromising the ultra-soft, silk-like hand feel that micro-denier yarns are known for. This yarn is a versatile base for high-density, premium fabrics in its Raw White state.

Application Fields

Warp Knitting: Ideal for high-speed tricot machines where micro-filaments require cohesion to prevent breakage.

Premium Linings: Used in luxury garment linings that demand both strength and a silky touch.

High-Density Weaving: Applied in "paper-touch" fabrics and ultra-light windbreakers.

Functional Base Layers: Used in thermal or moisture-wicking undergarments requiring high surface area.

Specification Overview

| Denier/Filament | 75D/72F |

| Intermingle | SIM (Slightly Intermingled) |

| Node Frequency | 35 - 55 knots/meter |

| Luster | Semi-Dull (SD) / Bright (BR) |

| Color | Raw White (RW) |

| Grade | Grade AA |

Production Process & Customization Service

Production involves precision drawing and low-pressure air-jet texturing. Customization includes:

Node Frequency: Nodes can be precisely adjusted to meet your specific knitting or weaving tension.

Oil Pick-Up (OPU): Adjustable from 1.5% to 4.0% for high-speed machine compatibility.

Shrinkage Tuning: BWS can be customized for specific heat-setting requirements.

Frequently Asked Questions (FAQ)

Q: Will the SIM nodes cause "shadowing" in the dyed fabric?

A: No, our SIM nodes are engineered to be subtle and are designed to soften during the dyeing process, ensuring uniform color distribution.

Q: Can I get this in Full Dull (FD) luster?

A: Yes, we can produce 75D/72F RW SIM in Full Dull to eliminate glare and provide a deep, matte appearance.

Based on the continuing flourish of business, the company was committed to our own brand and insists on good quality of DTY yarn. We are China 75D/72F RW SIM Polyester Yarn Manufacturers and Wholesale 75D/72F RW SIM Polyester Yarn OEM/ODM Suppliers. Covering an area of 15,000 square meters, the company has 30 DTY machines.

Mainly exported to over 30 countries such as Vietnam, Cambodia, Myanmar, South Korea, Ukraine, Russia, Morocco, the Philippines, Mexico and etc.Our main yarn products include polyester DTY yarn, polyester Sd yarn, high intermingled yarn, polyester raw material. They all meet the Grade A and Grade AA .

Color & Dyeing Methods

This yarn is optimized for piece dyeing. The Raw White base is produced from high-purity virgin chips, ensuring excellent dye levelness. The micro-filament structure allows for faster dye exhaustion, which can reduce energy consumption during the dyeing cycle in commercial textile mills.